| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | treasurewell MFG |

| Model Number : | MIM0008 |

| Price : | 0.2-2.1USD per pcs |

| Payment Terms : | T/T, Western Union, L/C, paypal |

| Supply Ability : | 1,000,000packs per month |

| Delivery Time : | 15-20 work days |

Factory price Mim metal powder injectioin parts metallurgy carbon steel ODM OEM for juice cup

Benefits of Using Titanium MIM Metal Injection Molding for Juice Cups

Lightweight and Durable - Titanium MIM metal injection molding provides a lightweight and durable material for juice cups, making it ideal for use in outdoor activities, travel, and daily use.

Corrosion-Resistant - Titanium is highly resistant to corrosion, making it an ideal material for use in juice cups that are exposed to acidic juices and other corrosive substances.

Excellent Biocompatibility - Titanium is a biocompatible material, making it safe for use in food and beverage applications, without the risk of contamination.

Customizable and Complex Shapes - Titanium MIM metal injection molding allows for the production of complex shapes and designs, making it possible to customize juice cups to meet the unique needs and preferences of customers.

Eco-Friendly - Titanium is a highly sustainable material that can be recycled and reused, reducing waste and environmental impact, and making it a popular choice for eco-conscious consumers.

Product Description:

Origin: Shenzhen, China - Our products are manufactured in our facility located in Shenzhen, China, ensuring high-quality production and timely delivery.

MIM Technology - We specialize in Metal Injection Molding (MIM) technology, which enables us to produce complex and intricate parts with a high degree of precision.

High Precision - Our MIM products are crafted with the utmost precision to meet the exact specifications of our customers.

Material: Stainless Steel - We use high-quality stainless steel in the production of our MIM products. Stainless steel is known for its strength, corrosion resistance, and durability, making it ideal for a variety of applications.

Short Delivery Time - We understand the importance of timely delivery and strive to ensure that our products are delivered within the shortest possible time frame.

Spare Parts Types: MIM + Machining - Our MIM products come with the additional benefit of machining. This ensures that the final product is of the highest quality and meets the exact specifications of our customers.

Expanding on the product description:

Our MIM products are made with cutting-edge technology and expertise. The MIM process allows us to create intricate and complex shapes with high precision, making our products ideal for a range of applications. Our stainless steel material is sourced from trusted suppliers, ensuring that our products are of the highest quality.

We understand that timely delivery is critical to our customers' success. That's why we have streamlined our production process to ensure that our MIM products are manufactured and delivered as quickly as possible.

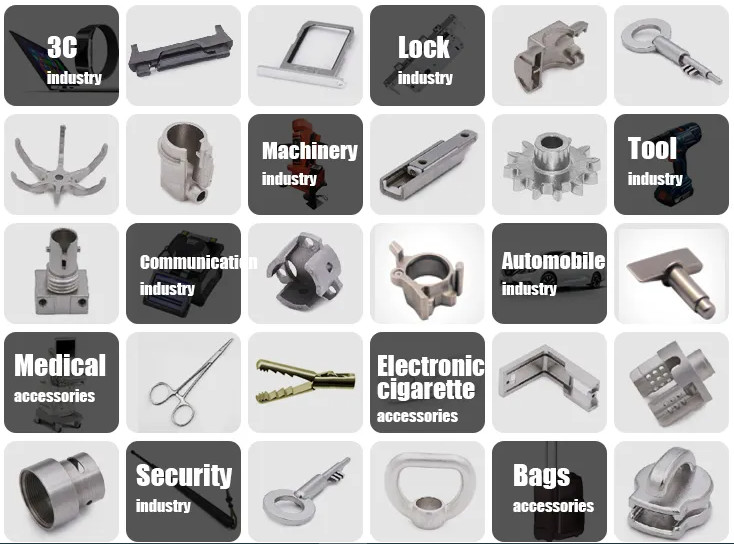

Our MIM products are suitable for a variety of industries, including automotive, medical, aerospace, and consumer goods. We offer a range of customization options to meet the specific needs and requirements of our customers. Our experienced team is available to discuss any special requests, ensuring that our customers receive the best possible service.

In addition to MIM technology, we also offer machining services, allowing us to produce parts that meet even the most demanding specifications. We work closely with our customers to ensure that every product we deliver meets their exact requirements.

At our facility in Shenzhen, China, we have a team of experts dedicated to quality control. All of our products undergo rigorous testing to ensure that they meet the highest standards of quality and performance. Our MIM products are durable, corrosion-resistant, and built to last.

Specification:

| Brand name | OEM & ODM |

| Product type | MIM parts |

| Product Model | MIM |

| Material | Stainless steel 304,316L,17-4PH,TI |

| Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

| Size | Custom |

| Tolerance | 10mm±(0.02-0.04)mm |

| Weight | ≤200g |

| Forming Method | metal Powder Injection Molding |

| Sintering method | Solid-phase sintering |

| Sintering environment | Vacuum |

| Mold material | Steel |

| Application | Decorative industry |

| Shape | Custom |

| OEM | Accept |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union, etc. |

| Lead time | 15-20 working days |

| Supply capability | 500000 Piece Per Month |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

====================================================================================

our sales team:

Manufacturing process: CNC stamping, CNC lathe, CNC milling, CNC machining, laser cutting, CNC MIM.

Drawing accepted: SOLIDWORKS, PROE, CAD, PDF, STP,IGS,

Quality assurance: ISO09001:2018, ROHS, TUV, IATF16949

Payment terms: by western union, paypal, T/T wiring, Payoneer, Moneygram.

Deliver terms: by UPS, Fedex, TNT, DHL, airfreight, seafreight.

|