| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | treasurewell MFG |

| Model Number : | MM0013 |

| Price : | 0.2-2.1USD per pcs |

| Payment Terms : | T/T, Western Union, L/C, paypal |

| Supply Ability : | 1,000,000packs per month |

| Delivery Time : | 15-20 work days |

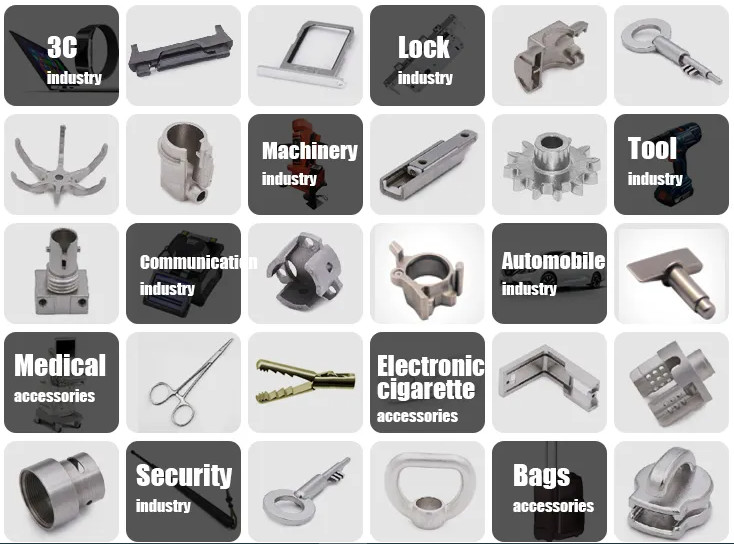

Factory price Mim metal powder injectioin parts metallurgy carbon steel ODM OEM for cavity

Metal Powder MIM Production is a manufacturing process that involves creating metal injection molding parts for use in cavity applications. This process involves injecting a mixture of metal powder and binder into a mold, and then heating it to remove the binder and sinter the metal particles together. The resulting metal part is highly accurate and has a high degree of strength and durability. Metal Powder MIM Production is ideal for creating complex shapes and parts with high strength requirements for use in cavity applications.

Product Description:

This product is a type of MIM (Metal Injection Molding) spare part made from high-precision stainless steel. It is produced in Shenzhen, China, and boasts a short delivery time. The MIM+machining combination ensures the part meets the required specifications with high precision.

The MIM technology used in producing the spare part involves injecting a mixture of powdered metal and binder into a mold. The mold is then heated to remove the binder and sinter the metal particles together, creating a highly accurate and durable part with a complex shape.

The stainless steel material used gives the spare part excellent corrosion resistance and mechanical properties, making it ideal for use in a variety of applications. Additionally, the short delivery time ensures that the part can be quickly integrated into production without causing delays.

Overall, this MIM spare part stands out for its high quality, precision, and fast delivery, making it a reliable solution for cavity applications.

Specification:

| Brand name | OEM & ODM |

| Product type | MIM parts |

| Product Model | MIM |

| Material | Stainless steel 304,316L,17-4PH,TI |

| Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

| Size | Custom |

| Tolerance | 10mm±(0.02-0.04)mm |

| Weight | ≤200g |

| Forming Method | metal Powder Injection Molding |

| Sintering method | Solid-phase sintering |

| Sintering environment | Vacuum |

| Mold material | Steel |

| Application | Decorative industry |

| Shape | Custom |

| OEM | Accept |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union, etc. |

| Lead time | 15-20 working days |

| Supply capability | 500000 Piece Per Month |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

=====================================================================================

product picture details and features:

our sales team:

Manufacturing process: CNC stamping, CNC lathe, CNC milling, CNC machining, laser cutting, CNC MIM.

Drawing accepted: SOLIDWORKS, PROE, CAD, PDF, STP,IGS,

Quality assurance: ISO09001:2018, ROHS, TUV, IATF16949

Payment terms: by western union, paypal, T/T wiring, Payoneer, Moneygram.

Deliver terms: by UPS, Fedex, TNT, DHL, airfreight, seafreight.

Client visiting gathering pictures:

|