| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | treasurewell MFG |

| Model Number : | MM0016 |

| Price : | 0.2-2.1USD per pcs |

| Payment Terms : | T/T, Western Union, L/C, paypal |

| Supply Ability : | 1,000,000packs per month |

| Delivery Time : | 15-20 work days |

Factory price Mim metal powder injectioin parts metallurgy carbon steel ODM OEM for cylinda 2

Feature: High-Quality Metal Parts Production with OEM Metallurgy MIM Metal Injection Molding for Cylinda 2

Precision and Consistency: The MIM process offers high precision and consistency in producing metal parts, ensuring that each part is made to exact specifications and meets the required standards.

Complex Shapes and Designs: MIM can produce complex shapes and designs that are difficult to achieve with traditional manufacturing methods. This allows for greater flexibility in design and increases the potential for innovation and improvement.

Cost-effectiveness: MIM is a cost-effective production method for metal parts, as it minimizes the amount of raw materials needed and reduces production time. This results in lower costs and improved efficiency for manufacturers, making it an attractive option for producing high-quality metal parts like Cylinda

Product Description:

Place of Origin: Shenzhen, China

Types: MIM (Metal Injection Molding)

High Precision: MIM technology offers high precision in producing metal parts, enabling manufacturers to produce parts to exact specifications and meet the required standards.

Material: Stainless Steel - This material is known for its durability, corrosion resistance, and strength, making it an ideal choice for producing metal parts.

Short Delivery Time: With advanced technology and efficient operations, manufacturers can produce and deliver parts in a short period, reducing lead time and improving customer satisfaction.

Spare Parts Types: MIM+Machining - Some parts require additional machining to achieve the desired shape and surface finish. The combination of MIM technology with machining can produce high-quality parts that meet the required specifications and standards.

Specification:

| Specification | Description |

|---|---|

| Tolerance | 10mm±(0.02-0.04)mm |

| Application | Decorative industry |

| Post-Sintering | Polishing, Wire-drawing, Sandblasting, Plating, Coated, etc. |

| Weight | ≤200g |

| Shape | Custom |

| Forming Method | Metal Powder Injection Molding |

| Material | Stainless steel 304, 316L, 17-4PH, TI |

| Mold material | Steel |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

| Sintering environment | Vacuum |

| Supply capability | 500000 Piece Per Month |

| Sintering method | Solid-phase sintering |

| Payment terms | T/T at sight, Paypal, Western Union, etc. |

| Size | Custom |

| Lead time | 15-20 working days |

| QC system | 100% inspection before shipment |

| OEM | Accept |

| Brand name | OEM & ODM |

| Product type | MIM parts |

| Product Model | MIM |

Customized OEM manufacturing Advantages:

Accepted OEM customized manufacturing to make the production for

all orders. real factory for over 20 years manufacturing

experience, is OK to do OEM, customized, one -stop manufacturing,

with own workshops for precison machining, precision MIM, precision

stamping, precison plastic, and blade sharpening and QC assembly

center. accepted customized to all metal related project and

product.

=====================================================================

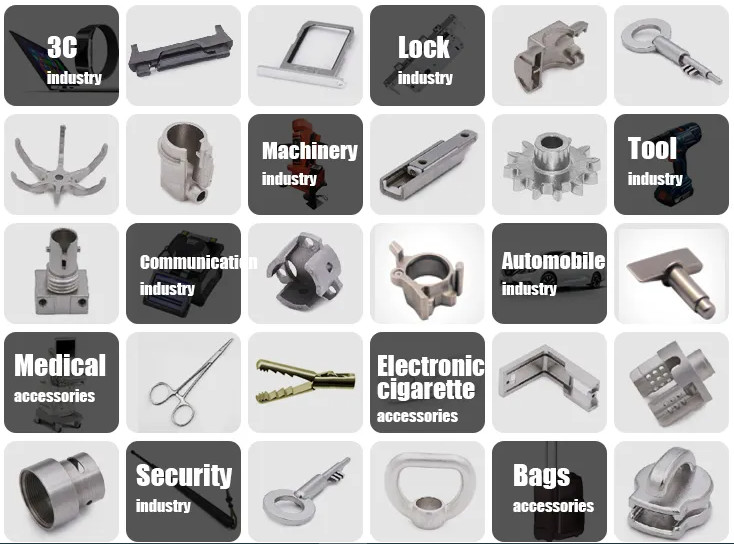

product picture details and features:

Manufacturing process: CNC stamping, CNC lathe, CNC milling, CNC machining, laser cutting, CNC MIM.

Drawing accepted: SOLIDWORKS, PROE, CAD, PDF, STP,IGS,

Quality assurance: ISO09001:2018, ROHS, TUV, IATF16949

Payment terms: by western union, paypal, T/T wiring, Payoneer, Moneygram.

Deliver terms: by UPS, Fedex, TNT, DHL, airfreight, seafreight.

|